Emission Measurement Equipment

How It Works:

- Sampling: A probe extracts a representative portion of the emission stream.

- Analysis: The sample passes through specialized analyzers that identify and measure specific pollutants, such as Carbon Monoxide, Nitrogen Oxides, and Particulate Matter (soot/smoke), based on their chemical or physical properties.

- Data Reporting: Results are processed, compared against government limits, and recorded. Large industrial systems are called CEMS (Continuous Emission Monitoring Systems).

Why We Use It

- Regulatory Compliance: To prove adherence to strict government emission standards, avoiding fines.

- Process Optimization: For combustion-based industries, measuring emissions helps engineers optimize fuel use for greater efficiency and lower operating costs.

- Air Quality/Health: To monitor and control the release of toxins, contributing to cleaner public air and better health outcomes.

Showing all 2 results

-

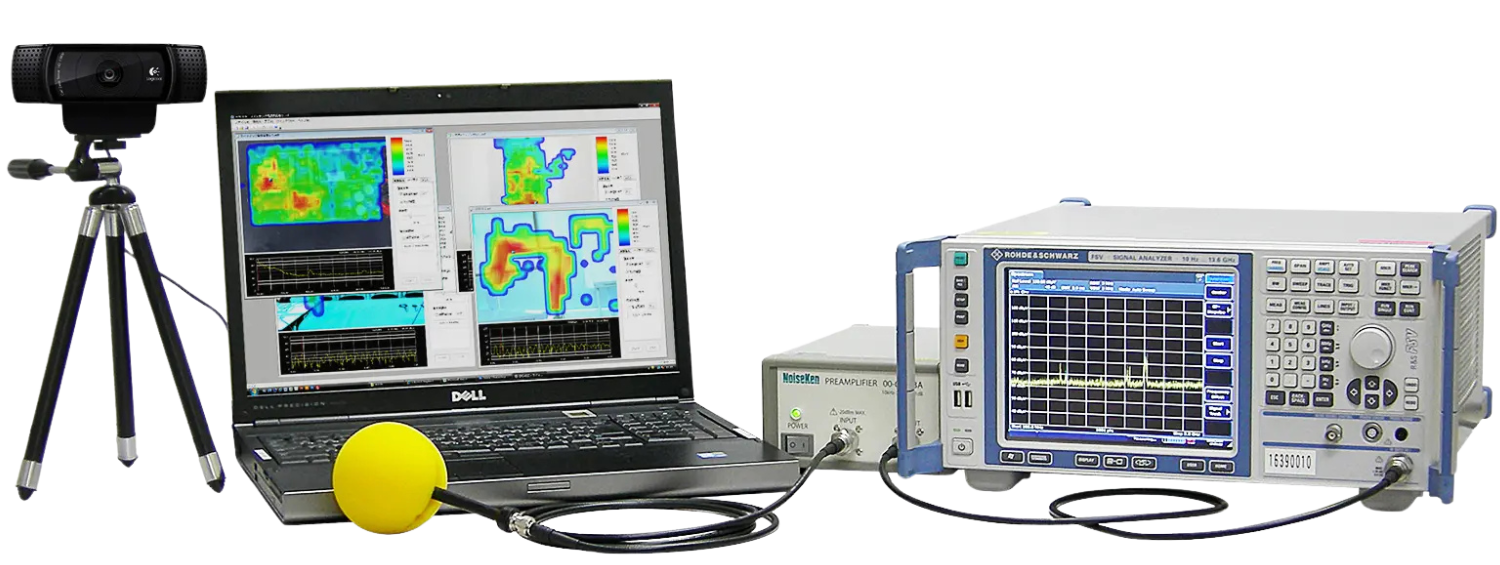

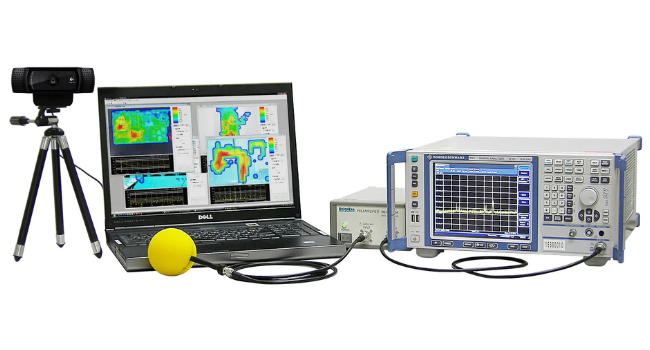

NoiseKen EPS-02Ev3 Electromagnetic Field Visualisation System

.Available on back-order

Availability: Stock models delivered next working day (UK only) for orders placed before 16:30 (Mon - Fri)

Read more -

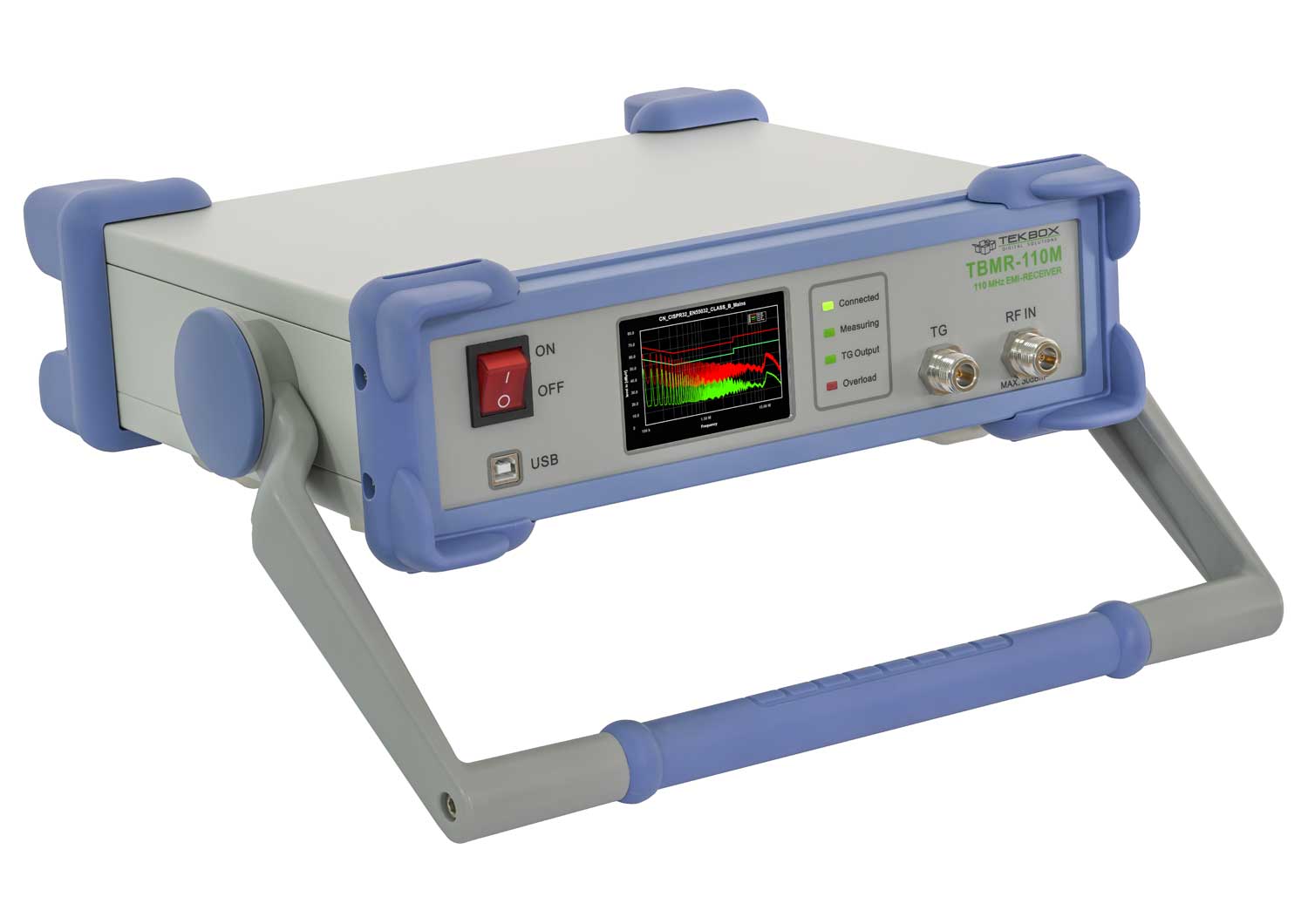

NoiseKen EPS-02Ev3s Simplified Electromagnetic Field Visualisation System

.Available on back-order

Availability: Stock models delivered next working day (UK only) for orders placed before 16:30 (Mon - Fri)

Read more

FREE SHIPPING £75+

FREE SHIPPING £75+

CELEBRATING 50+ YEARS

CELEBRATING 50+ YEARS

PRICE MATCH GUARANTEE

PRICE MATCH GUARANTEE